...

| Widget Connector | ||

|---|---|---|

|

...

Common problem affecting printing quality

...

Bad filament quality (e.g. brittle when filament absorbs moisture over time)

What Effect Does Moisture Have on 3D Printer Filament Storage?

...

How to quickly check if the PLA filament is wet

| Widget Connector | ||

|---|---|---|

|

Unsuitable Temperature

Nozzle temperature (melting point)

...

https://youtube.com/shorts/NNLzOippOxo?si=JDqaPiB26ZHYR8q6

Under-Extrusion

(source: Under-Extrusion | Simplify3D Software)

Over-Extrusion

(source: Over-Extrusion | Simplify3D Software)

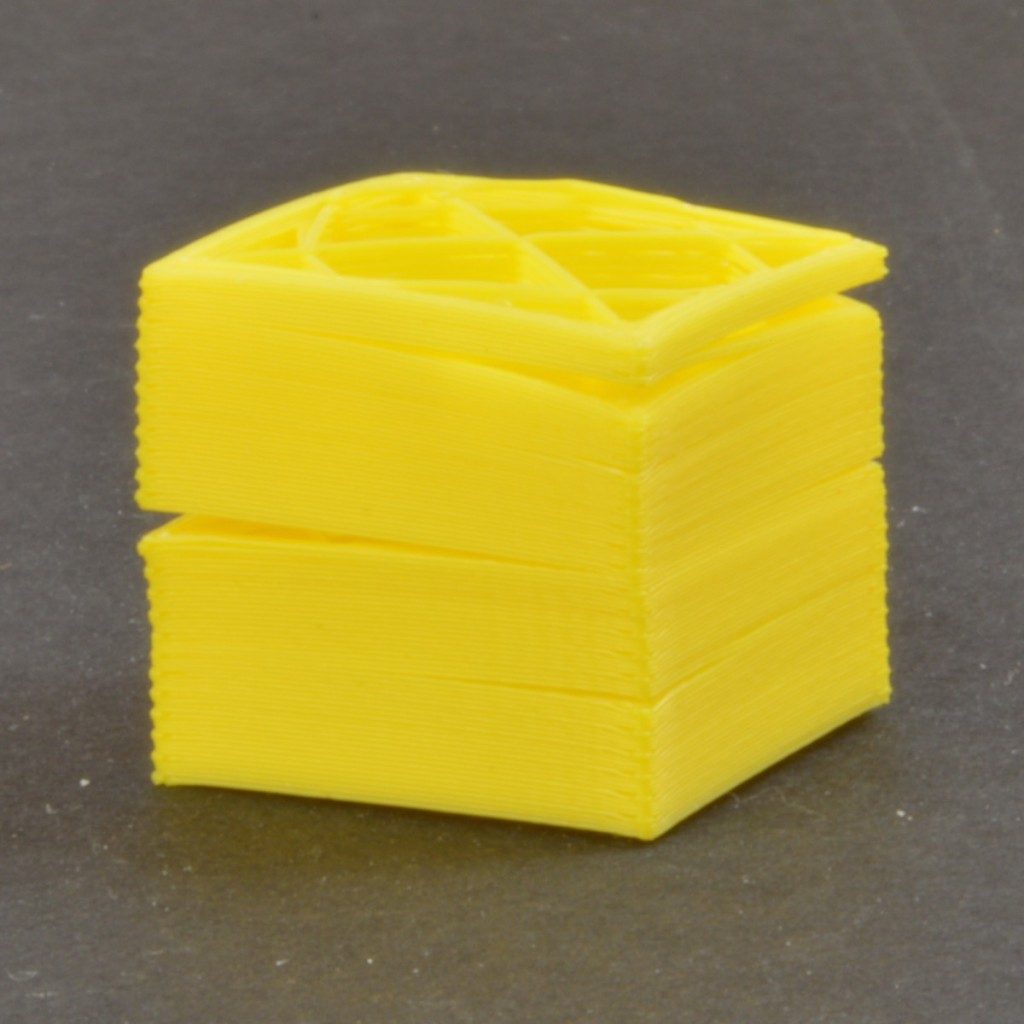

Overheating

(source: Overheating | Simplify3D Software)

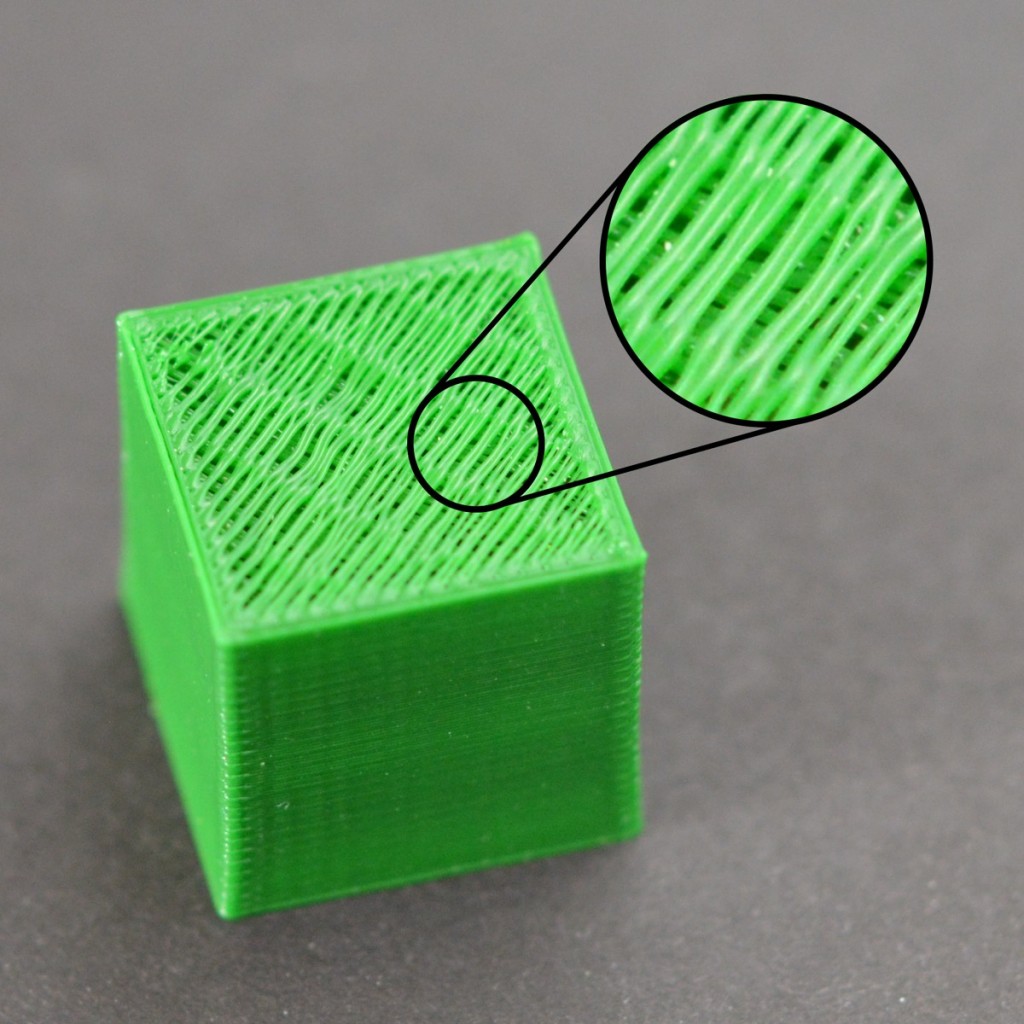

Gaps in Top Layers

(source: Gaps in Top Layers | Simplify3D Software)

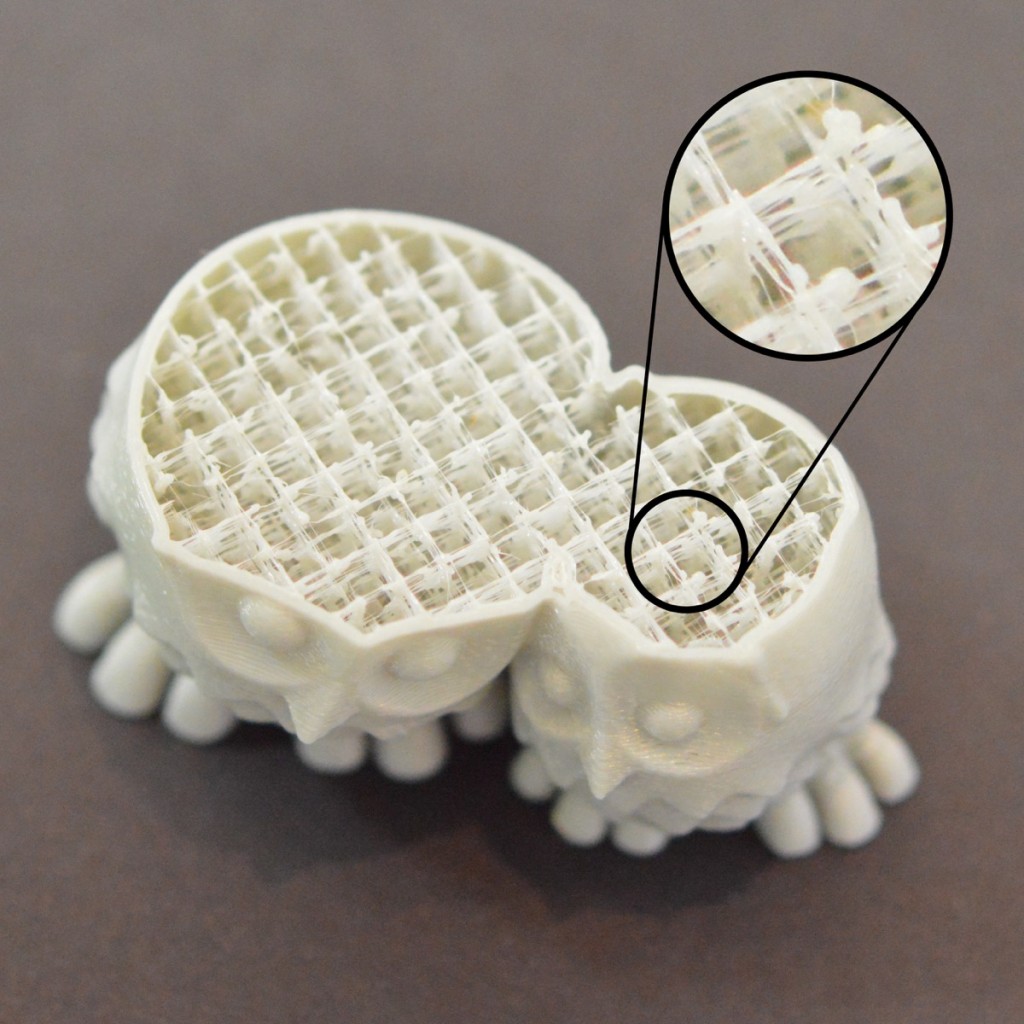

Weak Infill

(source: Weak Infill | Simplify3D Software)

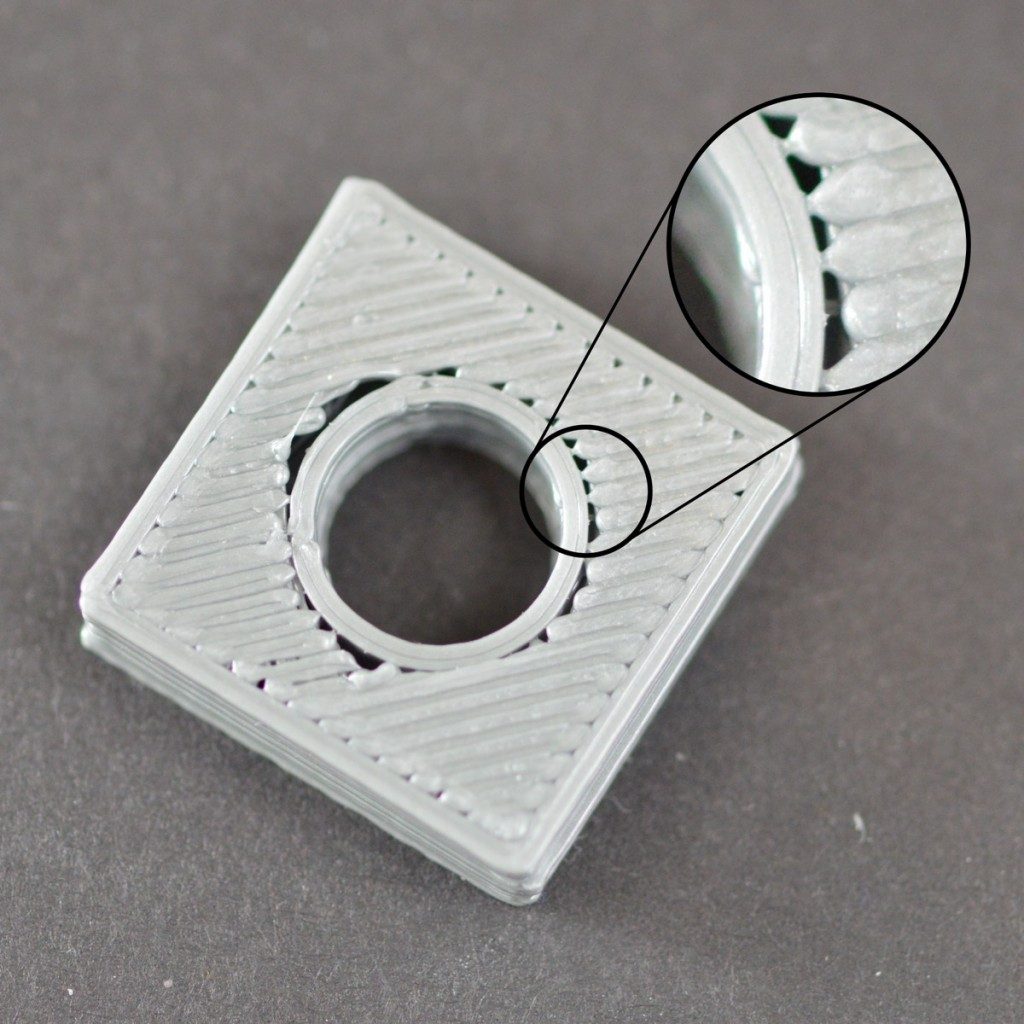

Gaps Between Infill and Outline

(source: Gaps Between Infill and Outline | Simplify3D Software)

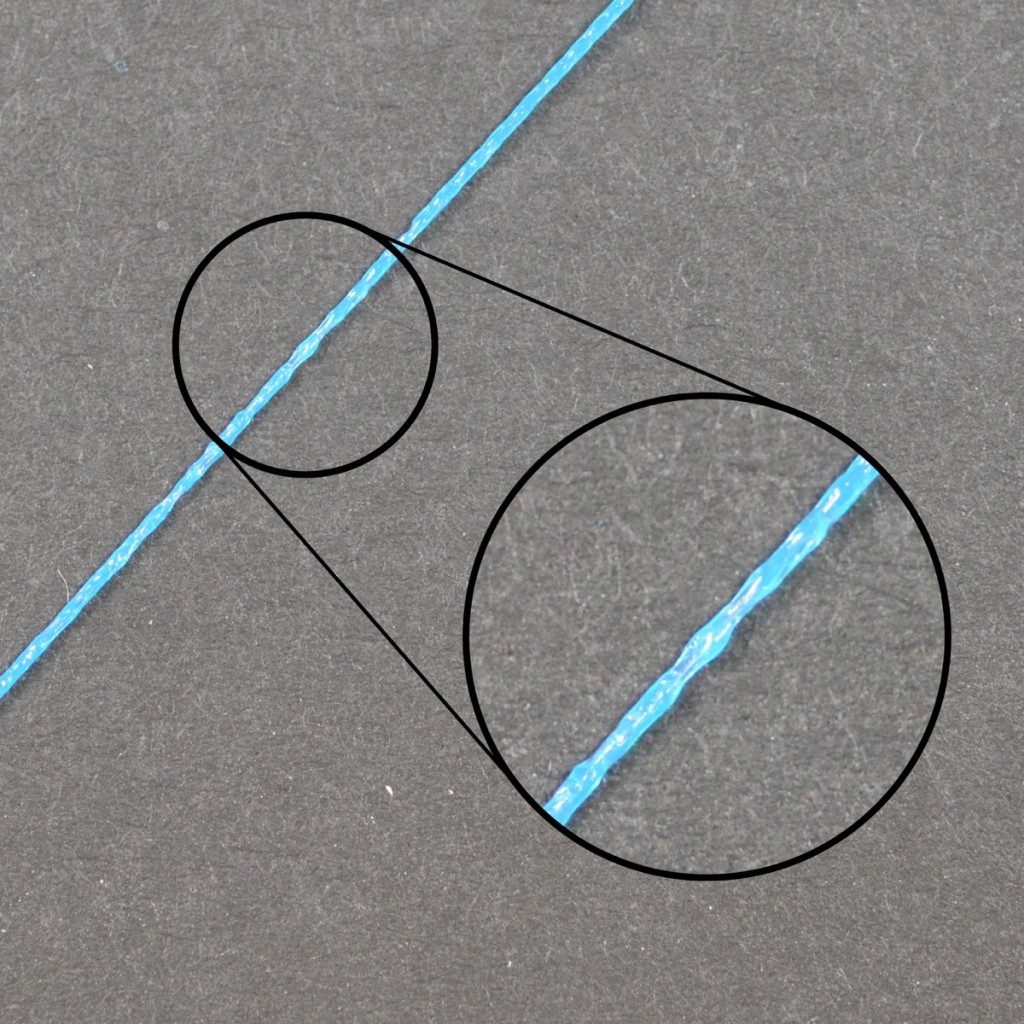

Inconsistent Extrusion

(source: Inconsistent Extrusion | Simplify3D Software)

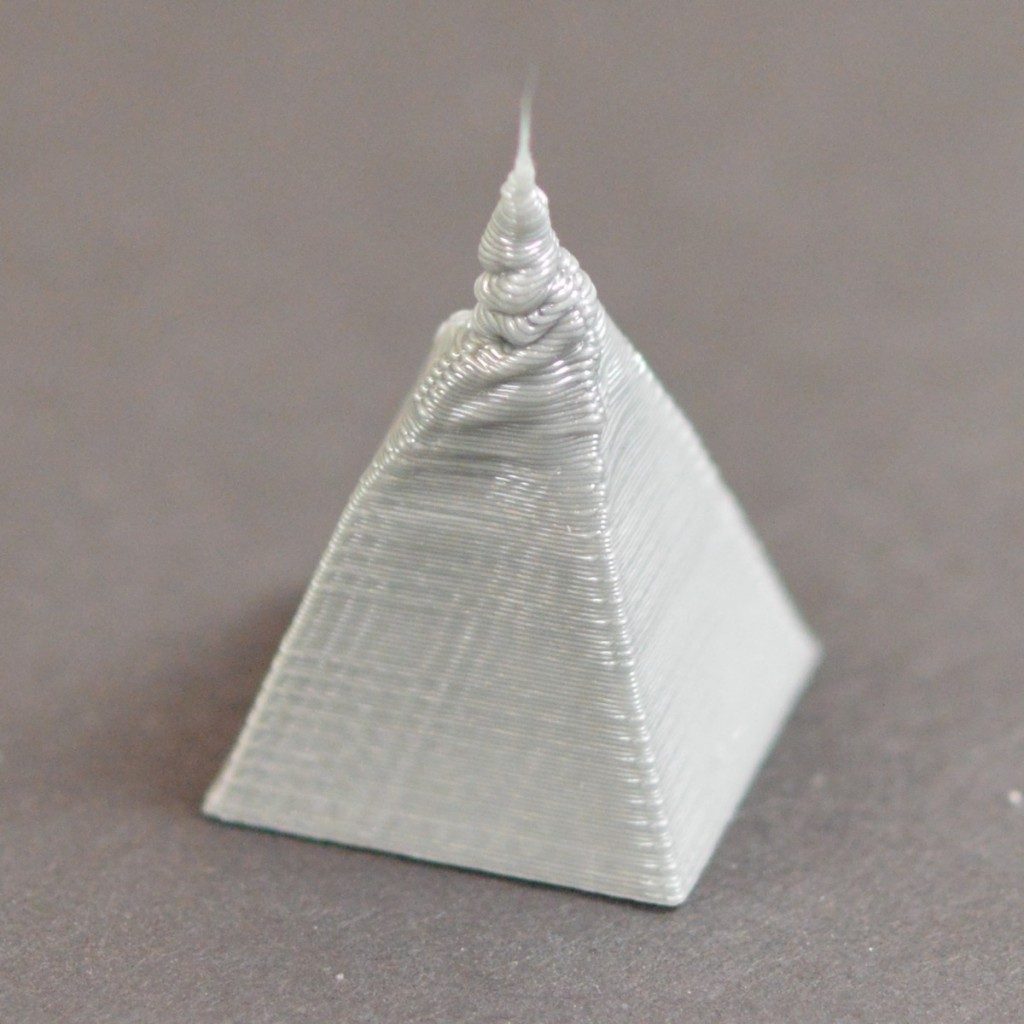

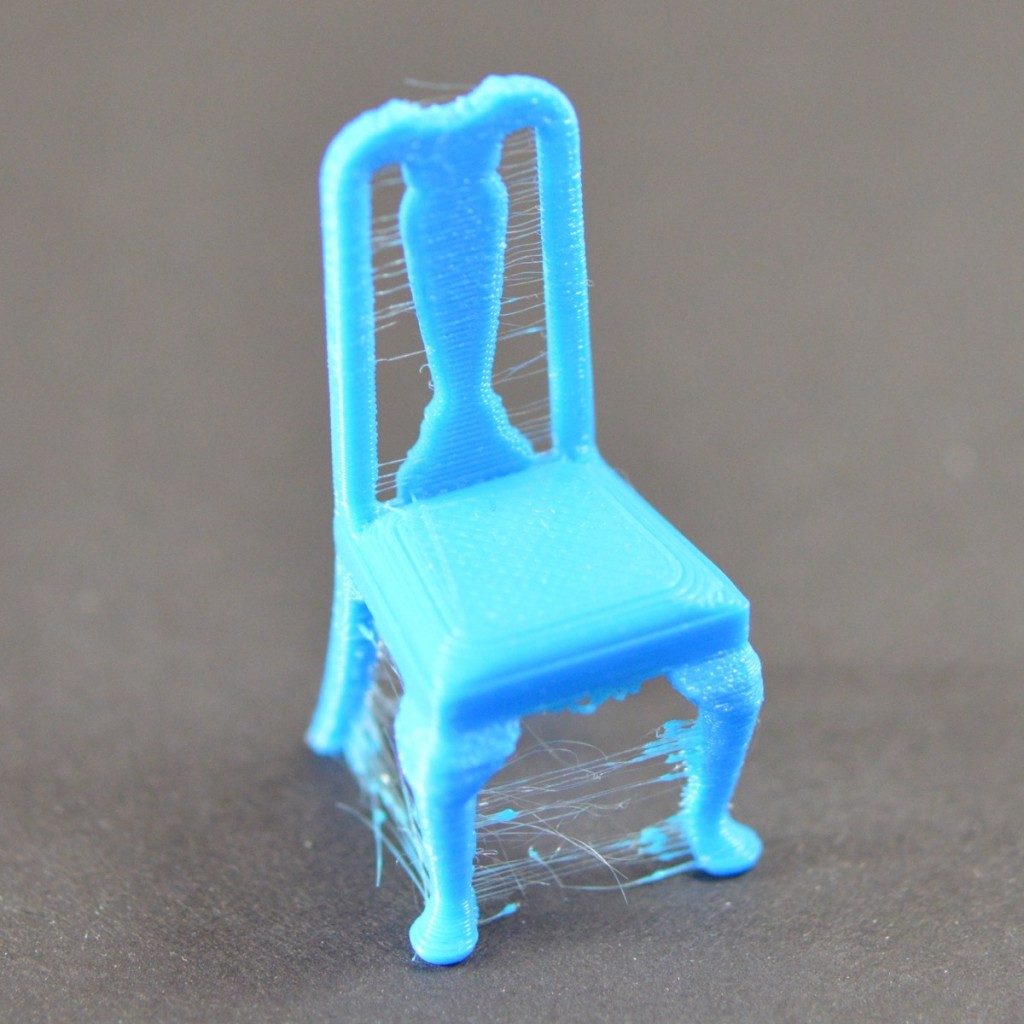

Stringing or Oozing

(source: Stringing or Oozing | Simplify3D Software)

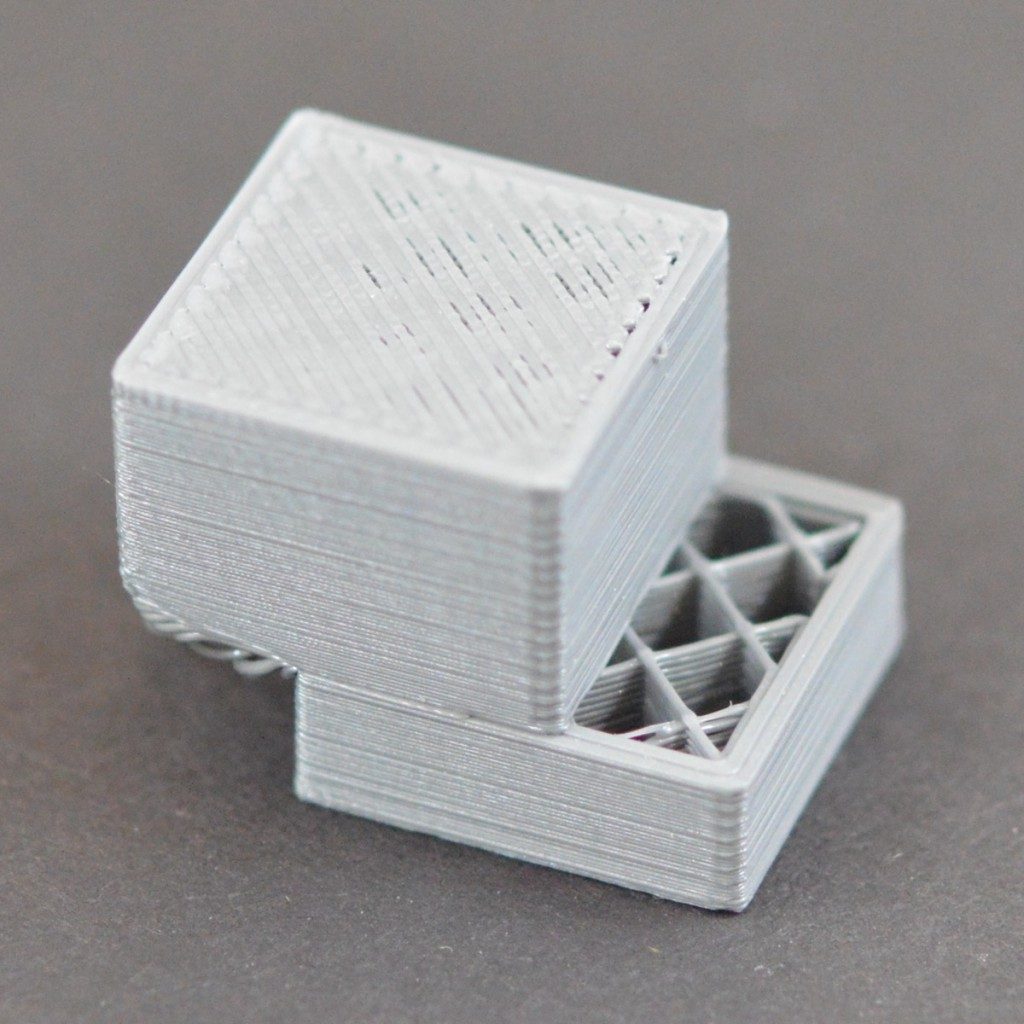

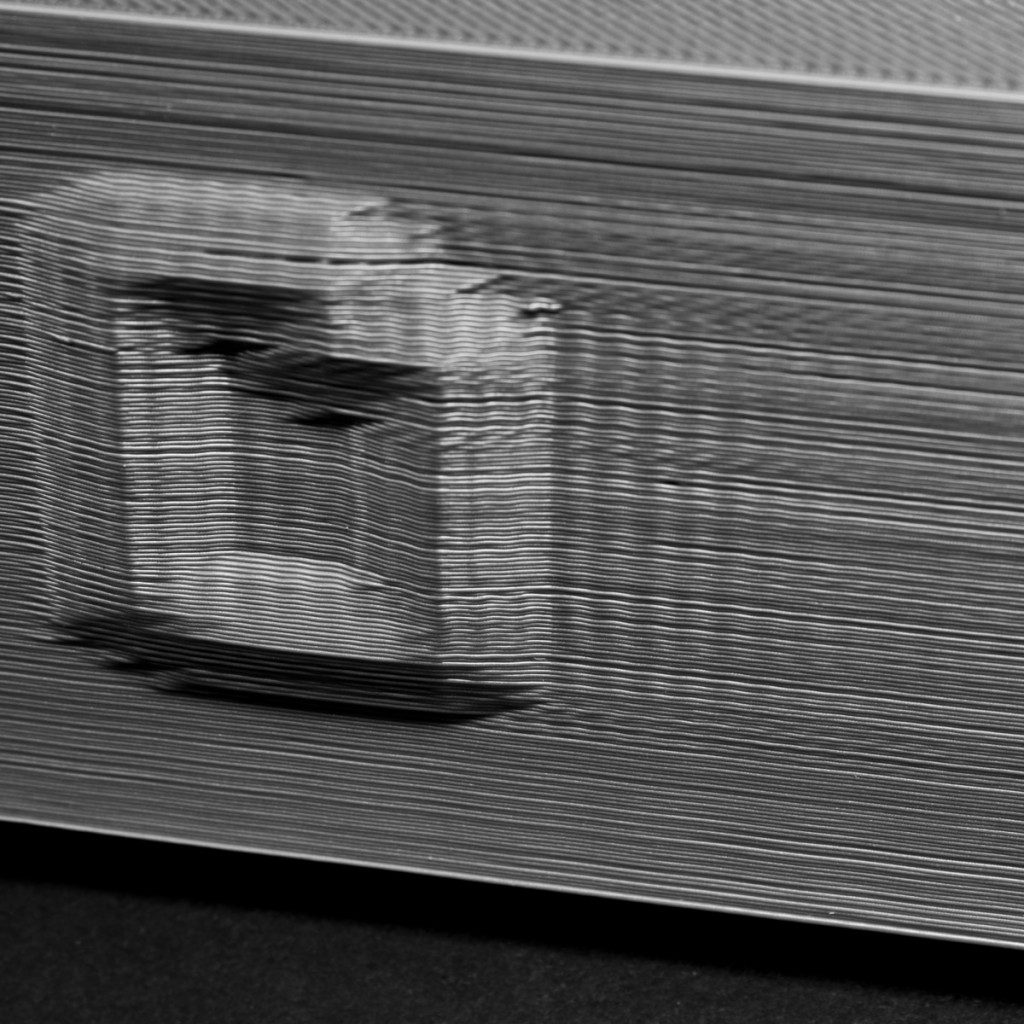

Layer Shifting

(source: Layer Shifting | Simplify3D Software)

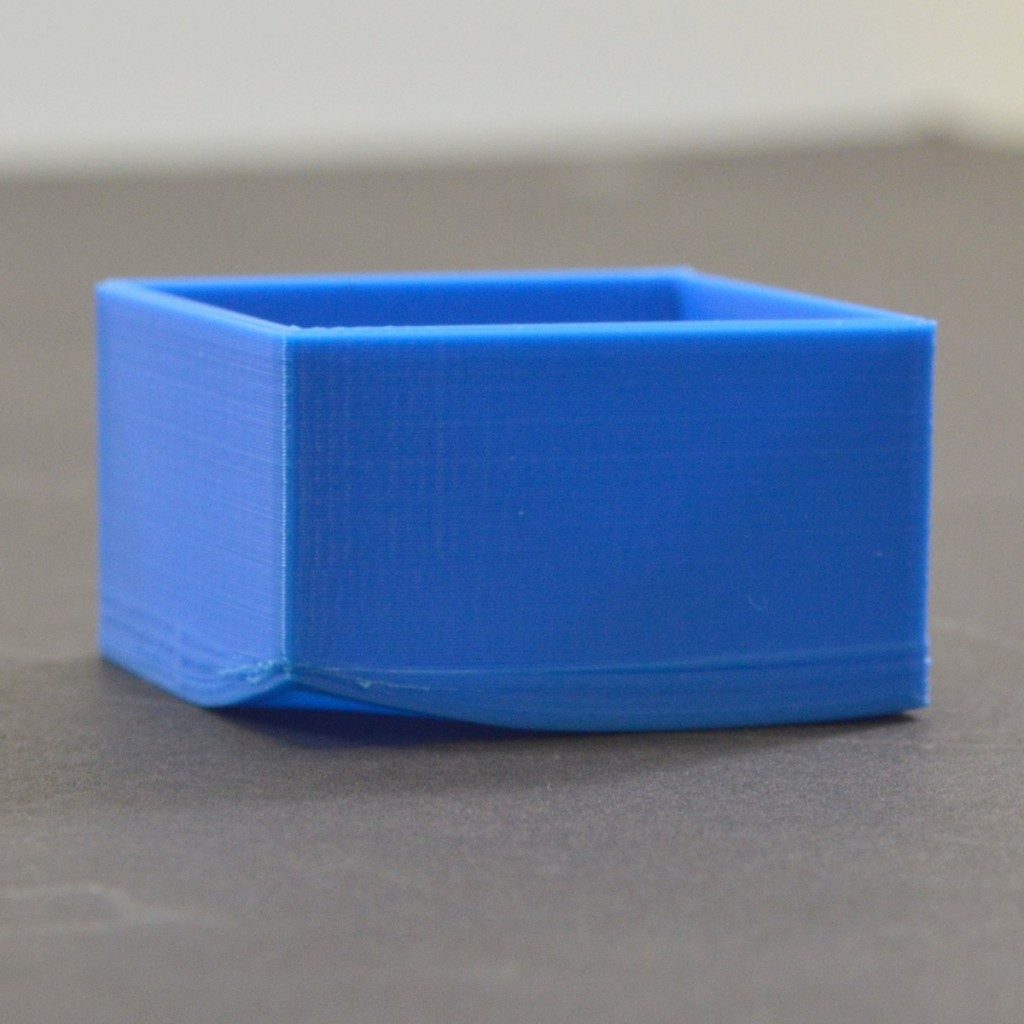

Warping

(source: Warping | Simplify3D Software)

Layer Separation and Splitting

(source: Layer Separation and Splitting | Simplify3D Software)

Vibrations and Ringing

(source: Vibrations and Ringing | Simplify3D Software)

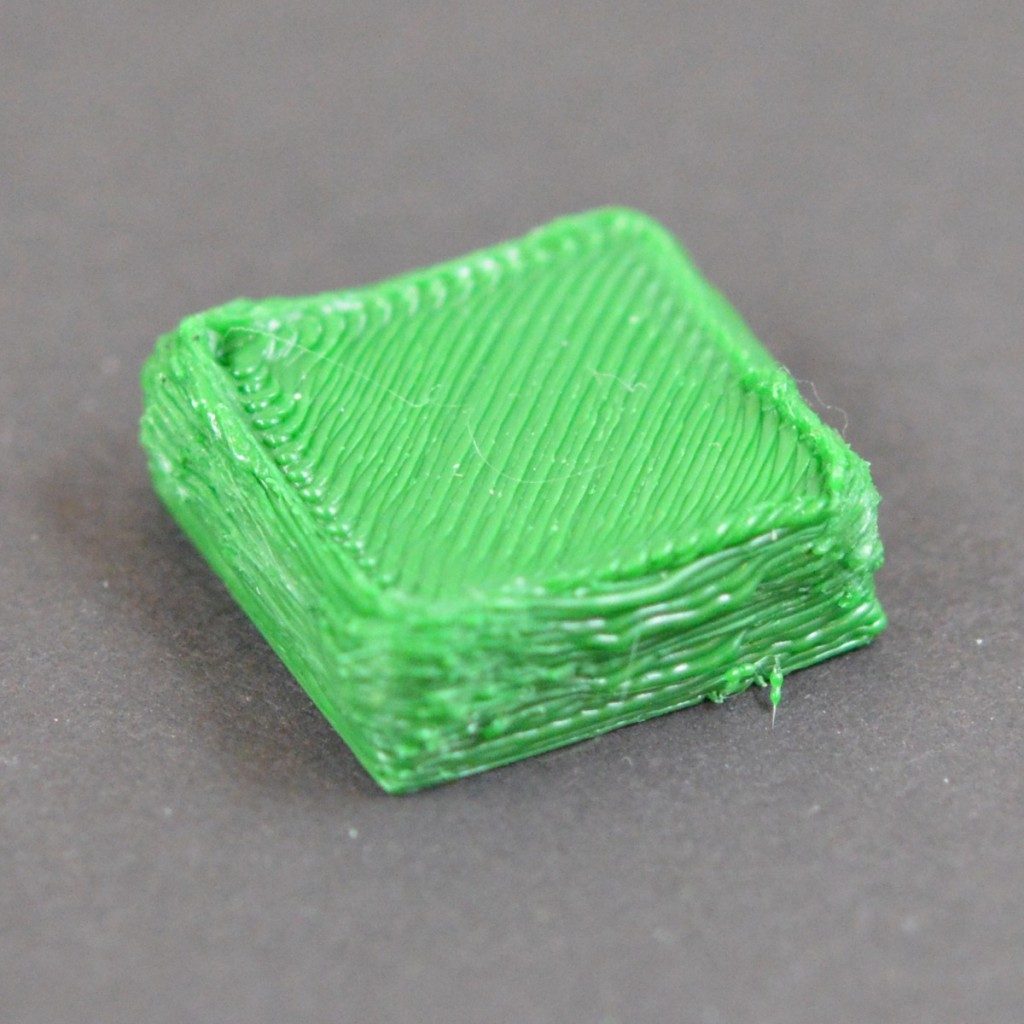

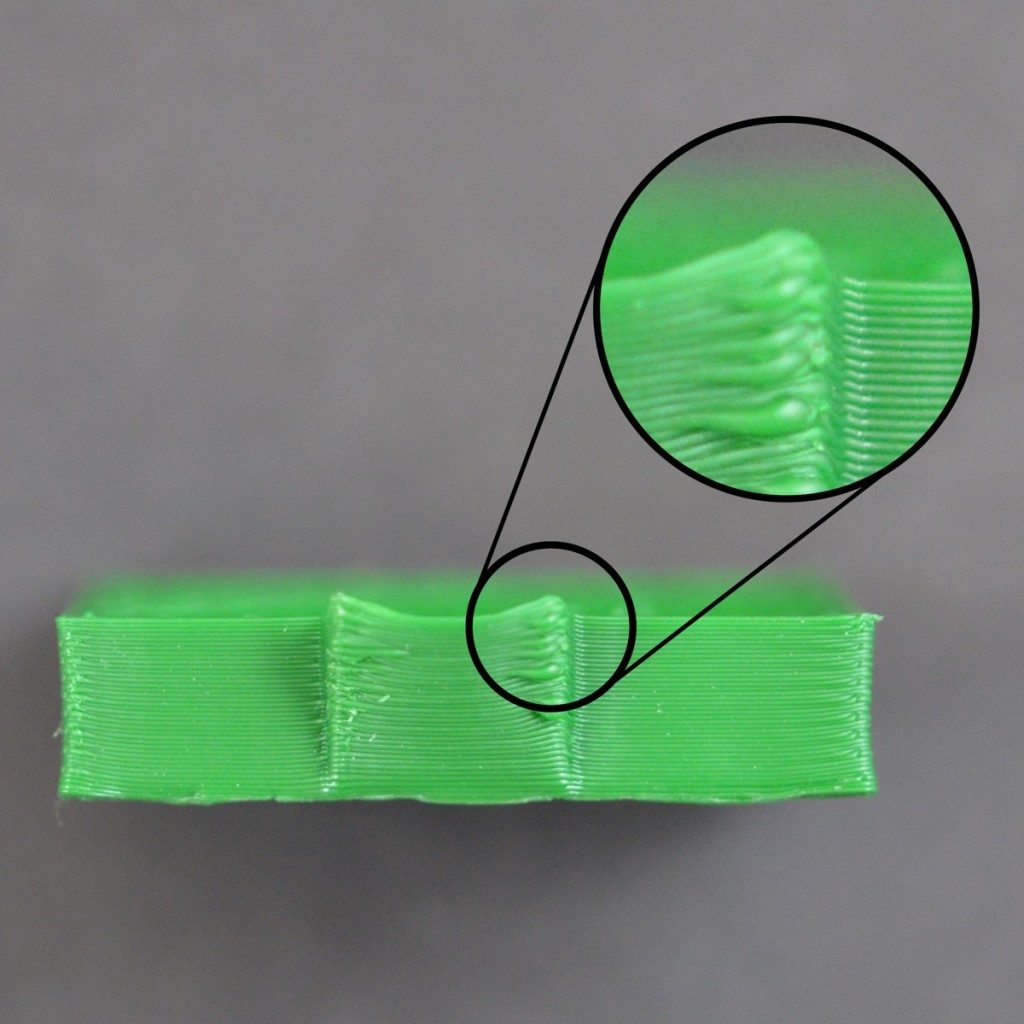

Curling or Rough Corners

(source: Curling or Rough Corners | Simplify3D Software)

More refers to: Print Quality Guide | Simplify3D Software

3D printing works smoothly when ALL the followings are satisfied:

- filament is brought by the "cold end" continuously and get into the "hot end" at the appropriate speed

- hot end is hot enough to melt the filament so that it can flow out continuously, but NOT too hot to make the material too "runny" or even burn them

- extruded material should stick to the heat bed or build plate at the first layer, or to previous layer of the object under construction

Refer to https://3dprinting.stackexchange.com/a/15950/41236 on what happens when "hot end" is too hot or too cold.