...

| Material | Properties |

|---|---|

| PLA (polylactic acid) | Excellent surface quality and detail. Mechanical and heat properties not suitable for some applications |

| ABS (acrylonitrile butadiene styrene) | Strong, ductile material with wear resistance and heat tolerance |

| Nylon (polyamide) | Strong yet flexible, with good chemical, impact, and abrasion resistance |

| PETG (polyethylene terephthalate glycol-modified) | Good toughness and wear resistance, with chemical resistance against many industrial fluids. |

| CPE (copolyester) | Durable and flexible with a glossy finish and good impact and heat resistance |

| PC (polycarbonate) | Strong and tough material with heat resistance up to 110 °C |

| TPU (thermoplastic polyurethane) | Flexible material with rubber-like properties. Provides high impact and wear resistance |

| PP (polypropylene) | Durable, tough, and fatigue resistant. Retains shape after torsion, bending, or flexing |

| PVA (polyvinyl alcohol) | Water-soluble material used to create supports for overhangs and cavities |

source: What is FFF 3D printing? - UltiMaker

...

The following is some introduction of Bambu support filaments:

Types of support filaments | Support W, i.e. Support for PLA | Support for PLA/PETG | Support G, i.e. Support for PA/PET | |

Types of body filaments that are compatible | PLA, PLA-CF, etc. | PLA, PLA-CF, PETG, PETG-CF, etc. | PLA, PLA-CF, PETG, PETG-CF, etc. | PA, PA-CF/GF, PA6-CF/GF, PAHT-CF/GF, PET-CF/GF, etc. |

Characteristics | 1. Easy to remove; 2. High surface quality; 3. Insensitive to moisture, and not strict with drying and moisture proofing | 1. Water-soluble, and suitable for those models that are not convenient to remove with hands and tools; 2. Easy to remove; 3. High surface quality; 4. Sensitive to moisture, and very strict with drying and moisture proofing. 5. Please refer to this wiki before use: PVA Printing Guide. | 1. Easy to remove; 2. High surface quality; 3. Sensitive to moisture, and very strict with drying and moisture proofing. | |

Recommended settings | 1. In most printing cases, it‘s recommended to print the support interfaces with support filaments, and print the support bases with body filaments, so that a lot printing time can be saved. 2. In some special printing cases, it's able to print both the support interfaces and the support bases, i.e. the whole support structures, with support filaments. However, it may leads to bad printing results when it comes to support structures that are thin and tall and deforming or falling during printing. | |||

*Bambu only have 1 nozzle, the following picture just for showing we can use support material for support part in FDM printing. Bambu is able to switch material on same layer by using AMS.

...

Bambu Slicer Introduction (Bambu Studio)

Installation

- Download Bambu Studio according to your PC operating system.

WindowsOS:View file name Bambu_Studio_win_public-v01.10.01.50-20241115162711.exe height 250

MacOS:View file name Bambu_Studio_mac-v01.10.01.50-20241115162711.dmg height 250

Alternative way:

Download in https://bambulab.com/en-us/download - Follow the instruction on Installation (No need to follow the version)

Windows:

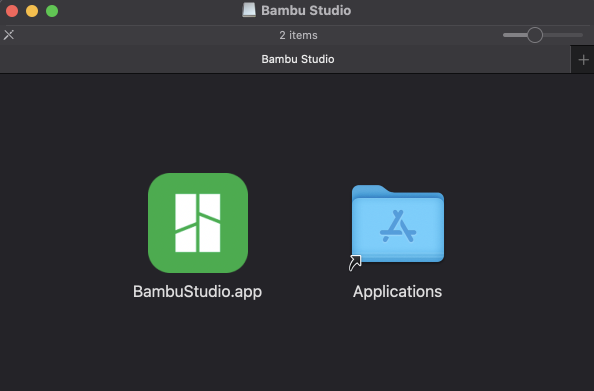

Mac:

simply open the .dmg file then copy the Bambu Studio app to the Applications folders on your Mac. - Open Bambu Studio

- Choose Asia-Pacific

- You can choose skip or Join the program, it doesn't matter

- Clear all selection, only choose Bambu Lab X1 Carbon 0.4mm nozzle

- Filament Selection doesn't matter, just click Next

- MUST install Network plug-in

- Click "Prepare" to switch to build plate view, make sure you choose the "Bambu Lab X1 Carbon 0.4 nozzle" and the plate type is "Smooth PEI Plate"

...

Orientation

View file name Task1.3mf height 250 Instruction:

Submit a Screen capture of the whole window, and a .gcode.3mf file with sliced models in Bambu studio. The orientation MUST need to be fixed so that it doesn't need any support in order to print the objects.Submission required:

a. Reply "Task 1, group member no. {Your group member no.}, {Your English Full Name}".

b. One modified .gcode.3mf file

c. One screen capture of the Sliced View showing support option enable but no support generated with correct orientation of the objects (Whole window screen capture in Preview session).

d. Your printer setting should choose "X1 Carbon 0.4 nozzle", and build plate should choose "Smooth PEI".Sense of selecting Sense of selecting support

Decide which is the best printing orientation by adding the support.

Original File:View file name Task2.3mf height 250

Correct answer: (support should be less than 0.5g)Instruction:

Submit a Screen capture of the whole window, and a .gcode.3mf file with sliced models in Bambu studio. Must use tree(auto) support mode, and need to select an extra option for the support (ONLY WITHIN THE Support-Support SECTION, do not modify any option in Support-Advanced), the best orientation should be less than 0.5g support. The surface of the bolt pattern is functional, so it must remain smooth, and must keep the original shape after printing.

Submission required:

a. Reply "Task 2, group member no. {Your group member no.}, {Your English Full Name}".

b. One modified .gcode.3mf file

c. One screen capture of the Sliced View showing support option enable and selected tree(auto) mode with option selected (Whole window screen capture in Preview session).

d. Your printer setting should choose "X1 Carbon 0.4 nozzle", and build plate should choose "Smooth PEI".Spherical print

Instruction:

Find a 3d model on the internet, with spherical structure.

Look at Variable Layer Height | Bambu Lab Wiki for reference, apply variable layer height to your 3d model, you can use either adaptive or smooth. Apply suitable support structure as well (depends on your 3d model).

Screen capture the sliced view with color scheme as "Layer Height" just like the following picture.Submission required:

a. Reply "Task 3, group member no. {Your group member no.}, {Your English Full Name}".

b. One modified .gcode.3mf file

c. One screen capture of the Sliced View showing the color scheme as "layer height", with suitable support structure apply to the sliced 3d model (Whole window screen capture in Preview session).

d. Your printer setting should choose "X1 Carbon 0.4 nozzle", and build plate should choose "Smooth PEI".Hole Tightness

View file name signal-2025-02-02-220739_003.mp4 height 250 You need to print a similar model at the end of this task, and submit it in the Fab Lab system, and also your printed product in the V104 collection box.

250Provided Material:

Please choose the corresponding base according to your number of group members (At least 2 ppl in a group)View file name Task4Base_4ppl.stp height 250 View file name Task4Base_3ppl.stp height 250 View file name Task4Base_2ppl.stp height 250 Instruction:

Printing file parameter limitation:

Number of group members 4 ppl 3ppl 2ppl Model Total Printing Time

(including preparation time)<1 hr <50 mins <40 mins Filament Estimation (grams) <18 <12 <8 If you submit a print file that is out of these range, I will request for your modification.

You should use the Task4Base_{}ppl.stp as the base, and draw the other missing parts by yourself.

You need to add hole for different layer:

First layer (the top prism in the sample):

The cylinder for first layer have radius of 1.5mm, as the prism should tightly fit to the cylinder, the hole should have 0.1mm extra in radius, which means the hole should have 1.6mm in radius, with 5mm as height.

Actually it do not needs to be a triangular prism, as long as it have the hole in correct size. This layer is just for preventing the layers fall off. However, please be remind that a complex shape will increase printing time, and use more filament.Second layer to fifth layer:

Number of group members 4 ppl 3ppl 2ppl Number of layers 4 3 2 Height per each layer piece 10 mm Total cylinder height 40mm 30mm 20mm The cylinder have radius of 2mm, as the polygon prisms should have a little bit loose in order to make it spinnable, the hole should have 0.2mm extra in radius, which means the hole should have 2.2mm in radius.

The height for each layer is 10mm.

Cylinder height for 4 ppl is 10 * 4 = 40mm. (So 3ppl is 30mm... and so on)For Each layer:

Can be any sided polygonal prism, it is formed by a polygonal prism minus a smaller polygonal prism so that it is hollow, and union with a tube with the 2.2mm radius hole.

The height must be 10mm.

Sample for forth layer:You also need to add 3D letter on top of the side surface.

The letter should align with the side surface, and must be consist of 5mm in height and 1mm in width in order for it to print clearly.

The sliced view must look like this in order for the extruded letter to print correctly.Required letter for layer except bottom layer:

First letter is your group member number submitted in the google sheet. If you are the no.1 in group, you should have your first letter as "1".

Starting from second letter, it would be your English Full Name initial. e.g. LCM stand for Lau Chiu Ming, and he is the no. 1 in group.

Bottom layer:Include your subject code (e.g. SD1105 should be "1105") at first surface (or first two surface depends on if there's not enough space).

Then the next surface should be your group number. E.g. group 1 should be "G1", group 2 should be "G2" and so on.

The next is the same as the other layer, your group member number and your English Full Name initial.

(For group of 2 ppl, the surface of each side faces may only enough for single letter, you can spread the subject code on the bottom layer, and the group number on the layer above. i.e. second layer: "G" "2" "1" "L" "C" "M", third layer: "1" "1" "0" "5" "2" "H" "C" "F")

Each group should submit 1 set (assembled), each person should make 1 layer piece.Extra (for student who like to challenge):

You can draw star shape instead of regular polygon, but keep in mind that the extruded letter should not be floating (no empty space between the letter and the intersection area of two surface).

Submission required:

a. Reply "Task 4, group member no. 1, {English Full Name}, group member no. 2, {English Full Name}, group member no. 3, {English Full Name}, group member no. 4, {English Full Name}" *according to how many group members you have

b. Submit the print job for only ONCE per each group.

c. Your printer setting should choose "X1 Carbon 0.4 nozzle", and build plate should choose "Smooth PEI".

Fill in all the required detail. Your modified .gcode.3mf file should have all the parts in one plate, and set the print sequence to "By object", enable "tree(auto)" support.

Make sure the filament amount and printing time is within the limitation mentioned above.

c

d. (In Print job form) One screen capture of the Sliced View View WITH Total printing time and Model printing time shown (Whole window screen capture in Preview session). If there's support, capture should show support section.

de. (In V104) After admin approve your print job, you can then go to V104 to send your print job to the available printers printers according to your group assigned timeslot. Assemble your print, and then put it into the corresponding submission box right next to the printer according to your subject code. Admin will add credits to your group account before your assigned printing time slot.

f. (Extra requirement for SD1105 students) You should submit a powerpoint in blackboard, with 3 or more than 3 captures capturing different angle of your layer piece.Printing time slot, also the deadline for Task 1-4 submission Group No. 1 - 12 13 - 24 25 - 36 SD4410 Feb 10- 2326- SD5978 Feb 10-23 2326- - SD5512 Feb 1013-23 2628- - SD1105 Feb 24- Mar 9Mar 912