...

- An additive manufacturing process for construction of 3D object from CAD file

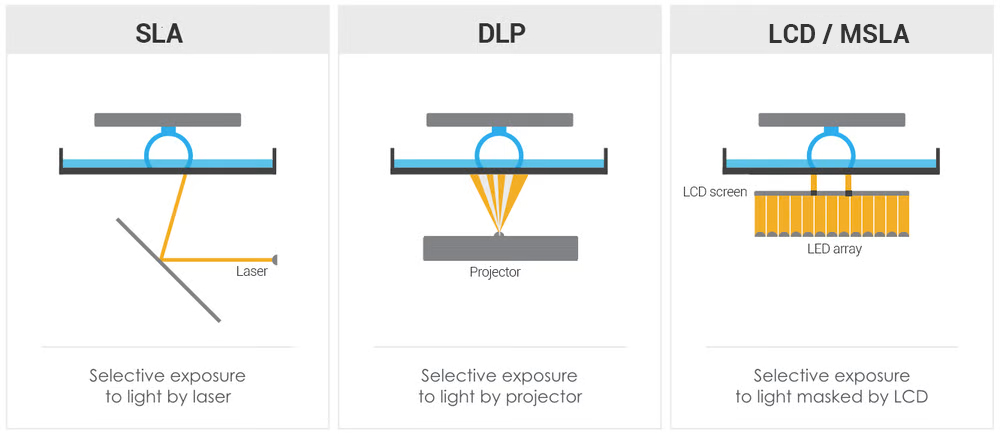

- Different techniques of 3D printing, including

- Fused Filament Fabrication (FFF) or Fused Deposition modeling (FDM) (https://3dprinterpower.com/fff-vs-fdm/)

- Stereolithography (SLA), DLP or LCD (https://all3dp.com/2/dlp-3d-printer-digital-light-processing-explained/) - resin-based approach

- Selective Laser Sintering (SLS) (https://youtu.be/sRC8W77MlrY?si=oVZ7CkE36utrWrUR) - powder-based approach

Widget Connector url https://www.youtube.com/watch?v=sRC8W77MlrY - Comparison between FDM, DLP, SLA

Widget Connector url https://www.youtube.com/watch?v=3lRhZTdafE4 - More printer types

Widget Connector url https://www.youtube.com/watch?v=DMWzMpjSJLM

...

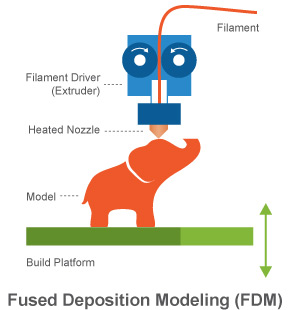

How does FFF/FDM work?

(source: https://all3dp.com/2/fused-filament-fabrication-fff-3d-printing-simply-explained/)

Widget Connector url http://youtube.com/watch?v=Z70SF4guWKo

(source: How Does The FDM 3D Printing Technology Work? | Manufactur3D)

...

- Filament is brought in by "cold end" and heat up to molten form at "hot end" and squeeze out through nozzle

- Squeezed out molten material (extruded material) get deposited onto the 3D object under construction, layer by layer

(source: Fused Filament Fabrication – Simply Explained | All3DP)

...

- The detail of finished prints is limited by the size of the nozzle. Other technologies offer higher detail.

- The strength of finished parts is limited because each layer is joined to the layer below it.

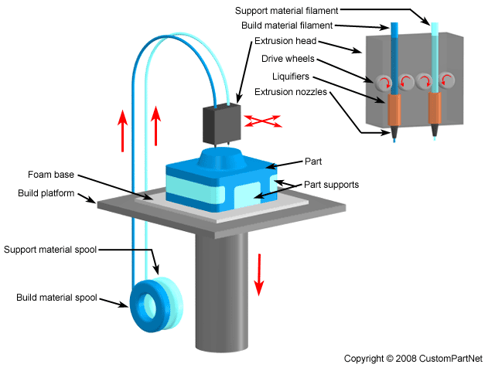

- Need to waste some support material due to gravity

(source: Introduction to Fused Deposition Modeling (FDM) - University of Maryland) - Have layer pattern on the side

...

*Bambu only have 1 nozzle, the following picture just for showing we can use support material for support part in FDM printing. Bambu is able to switch material on same layer by using AMS.

(source: A Guide to FDM Printale Plastics and 3D Printing Filament | 3devo)

...

| Widget Connector | ||

|---|---|---|

|

...

Factor affecting printing quality

Filament quality (e.g. brittle when filament absorbs moisture over time)

What Effect Does Moisture Have on 3D Printer Filament Storage?

(source: What Effect Does Moisture Have on 3D Printer Filament Storage?)

PETG quality difference with different moisture contamination

Widget Connector url https://www.youtube.com/watch?v=Ql1oN3XyrZg&t=19s

Flow Rate and Filament Moisture

Mass flow rate is directly correlated with the moisture content of 3D printed filament. Higher moisture content yields the lowest viscosity and the highest mass flow rate.

While high flow rates are generally desirable, an unregulated flow rate leads to over extrusion.

Indications of Possible Moisture Content in Failed 3D Printing Builds

- Filament cracks or makes popping noise as the filament is pushed through the extruded

- Holes in the top of parts

- Extruder tip bubbles with a tiny burst of steam, stringy or drooly

- The filament will not adhere to the print bed

- Repeated builds seem inconsistent or fail no changes in variables

- Extruder motor stops but filament keeps coming out

- Extruder motor starts but filament extrusion is delayed

- Parts become soft, fragile, and break easily

- Extruder jams

How to quickly check if the PLA filament is wet

| Widget Connector | ||

|---|---|---|

|

Nozzle temperature (melting point)

whether printing material is melt properly

heat bed or build plate temperature (glass transition temperature)

whether extruded material can stick onto the build plate

enclosure temperature

whether temperature of the object under printing can be properly controlled so that extruded material can stick to subsequent layers

Clogged in extruder

| Widget Connector | ||

|---|---|---|

|